From Prototyping to Mass Production: The Phases of the Production Cycle

Discover how product prototyping accelerates development, optimizes costs, and ensures quality, from design to mass production. 20-12-2024

In the industrial sector, transforming an idea into a successful product requires a structured process and the use of advanced technologies. Each phase of a product’s production cycle, from design to mass production, plays a crucial role in ensuring efficiency, quality, and sustainability. Let’s explore this journey, analyzing the key stages and their impact on the final product.

Design: Shaping the Idea

Design is the initial and most critical phase of the product production cycle. Here, technical, functional, and aesthetic requirements are defined, and materials and manufacturing techniques are selected to ensure industrial feasibility. Engineering consultancy plays an essential role: an experienced partner can guide the team in selecting solutions that optimize the design and make the product suitable for both small and large-scale production. This strategic phase lays the foundation for success, anticipating potential challenges.

Prototyping: Testing Innovation

Prototyping turns the concept into a tangible product, enabling the verification of its characteristics and performance evaluation. Advanced technologies such as CO₂ and fiber laser cutting allow for the rapid and cost-effective creation of prototypes. This approach facilitates practical testing, identifies potential improvements, and enables modifications before proceeding to the next phases. The speed and precision of this phase are critical for accelerating product development.

Pre-Series Production: A Strategic Transition

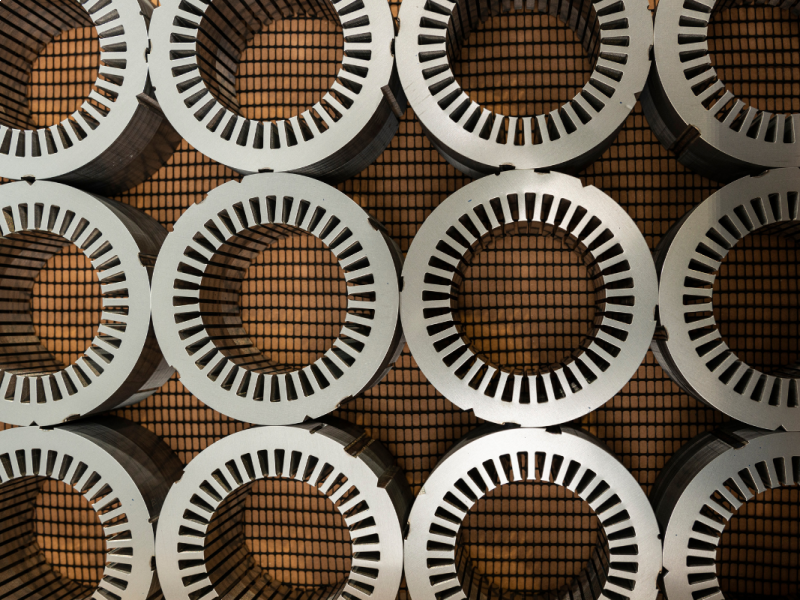

Pre-series production represents a key validation stage. Produced on a limited scale, this phase allows for the product’s effectiveness to be tested under real-world conditions. Single-notching technology enables the production of high-quality components without the need for costly progressive dies, ensuring flexibility and speed. Pre-series production also provides an opportunity to test market responses and optimize production processes.

Mass Production: Large-Scale Efficiency

Once the pre-series has been approved, the process moves to large-scale production. This phase requires investments proportional to the projected sales volumes. Techniques such as progressive dies optimize unit costs, making production more efficient as volumes increase. Precision and automation are essential to maintaining high standards and ensuring consistent market competitiveness.

Quality Control: Ensuring Excellence

In every phase of the production cycle, quality control is critical to delivering a final product that meets the highest standards. Rigorous testing of materials and production processes helps prevent errors and builds customer trust. A well-organized control system not only enhances efficiency but also contributes to building a strong and reliable reputation.

Continuous Improvement: Staying Competitive

The product’s production cycle does not end with manufacturing. Monitoring market performance and gathering feedback helps identify improvement opportunities and drive continuous innovation. This proactive approach ensures the product remains competitive and meets evolving customer needs.

From design to mass production, every phase of the product production cycle is a fundamental step towards achieving excellence. With advanced technologies, rigorous process control, and a strategic approach, it is possible to create products that not only meet market expectations but also drive it towards new frontiers of innovation and quality.