The Importance of Process Control in Customized Electric Motor Manufacturing

Discover the importance of process control in electric motor manufacturing to guarantee precision, efficiency, and reliability at every stage of production. 12-03-2025

Every customized electric motor is the result of a manufacturing process that must ensure precision, efficiency, and reliability. To produce a motor that meets specific customer requirements, it is essential to implement continuous and rigorous monitoring at every stage of production.

Effective process control ensures that every component meets the required technical specifications, while also optimizing production, reducing waste, and improving final performance.

By integrating advanced technologies and a structured quality management system, manufacturers can guarantee a high level of safety and reliability in every motor produced.

Quality Control at Every Production Stage

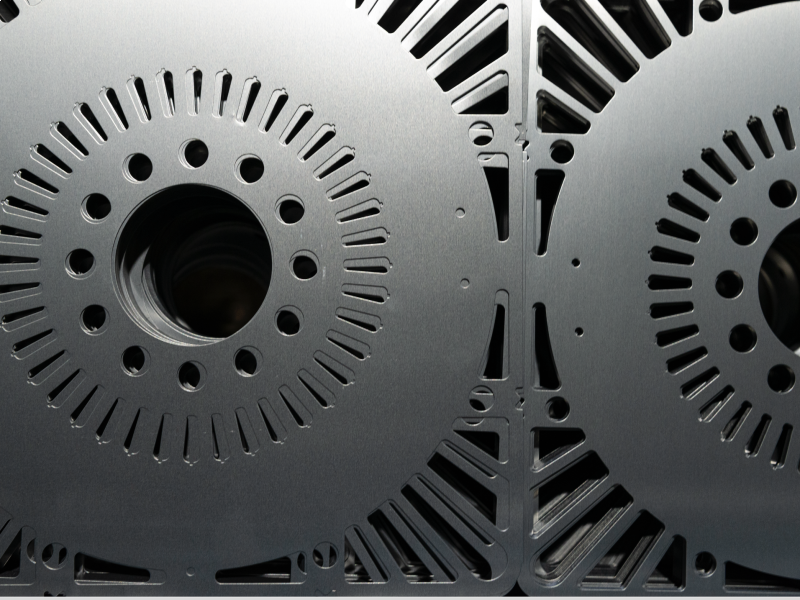

Ensuring the quality of a customized electric motor requires monitoring every step of the manufacturing process. Each detail, from material selection to lamination processing and final assembly, must meet strict precision standards.

In stator and rotor manufacturing, for example, dimensional inspections are performed to verify that geometric tolerances are met. Measurements are conducted on selected samples throughout the production line, minimizing the risk of defects and ensuring product uniformity.

Advanced Tools and Technologies for Precise Measurements

Achieving high-quality results depends on the use of state-of-the-art measurement tools. Our metrology department is equipped with cutting-edge instruments to conduct accurate inspections on every component.

- Coordinate Measuring Machines (CMMs): High-precision devices that assess geometric tolerances with extreme accuracy.

- Optical Metrology Systems: Used to examine the microscopic characteristics of laminated components, detecting potential imperfections.

- Magnetic Characterization Systems: Essential for analyzing the electromagnetic properties of materials and stators, ensuring optimal motor efficiency.

These tools not only ensure that each component meets the required technical parameters, but also enable the early detection and correction of anomalies, preventing waste and reducing production costs.

Product Traceability and Identification

A critical aspect of customized electric motor production is component traceability. To maintain full control, each stator and rotor is marked with a laser-engraved identification code, allowing for complete traceability across the entire production batch. This system enables real-time monitoring of every unit, facilitating rapid intervention when needed, and providing customers with the certainty of a certified and reliable product.

Customer Complaint Management & Continuous Improvement

Process control extends beyond production and into customer relations. Complaint management is a key opportunity to identify areas for improvement and enhance overall product quality. Every reported issue is fully addressed until the customer is completely satisfied, reinforcing our commitment to continuous improvement and excellence.

In the customized electric motor industry, process control is the cornerstone of efficiency, reliability, and precision. By leveraging advanced measurement tools, implementing continuous monitoring, and maintaining a rigorous focus on quality, we deliver tailor-made solutions that meet each customer’s unique needs. Investing in strict process control is not just a strategic choice—it is a guarantee of excellence.