Process control - Quality without compromise

We want to offer the highest quality to our customers to help them ensure the quality of their motors." This is the motto that is repeated daily in VMF.

VMF has always focused on quality and over time has obtained Certifications such as ISO 9001 to testify the quality of the production process and the constant search for continuous improvement. For this reason, the complaints handling process is a key point of focus for VMF, ensuring that each report is closed only when the customer gives its approval.

In order to ensure the quality of products, a check on all production stages and shipments takes place in a random samples basis; these checks cover both geometric and electromagnetic tolerances.

VMF has always invested in quality, and in fact within its metrological laboratory we find a wide range of measuring equipment:

Tasting probes:

State-of-the-art measuring machines equipped with cutting-edge technology needed to perform very accurate measurements at high speed.

• Miitutoyo (1200x2000 mm)

• Hexagon (850x300 mm)

Optical detector measuring machine:

Its optical system allows greatly enlarged images to measure the dimensions and microscopic characteristics of the laminations produced by the VMF

• CNC VISION MEASURING SYSTEM - Mitutoyo (600×650 mm)

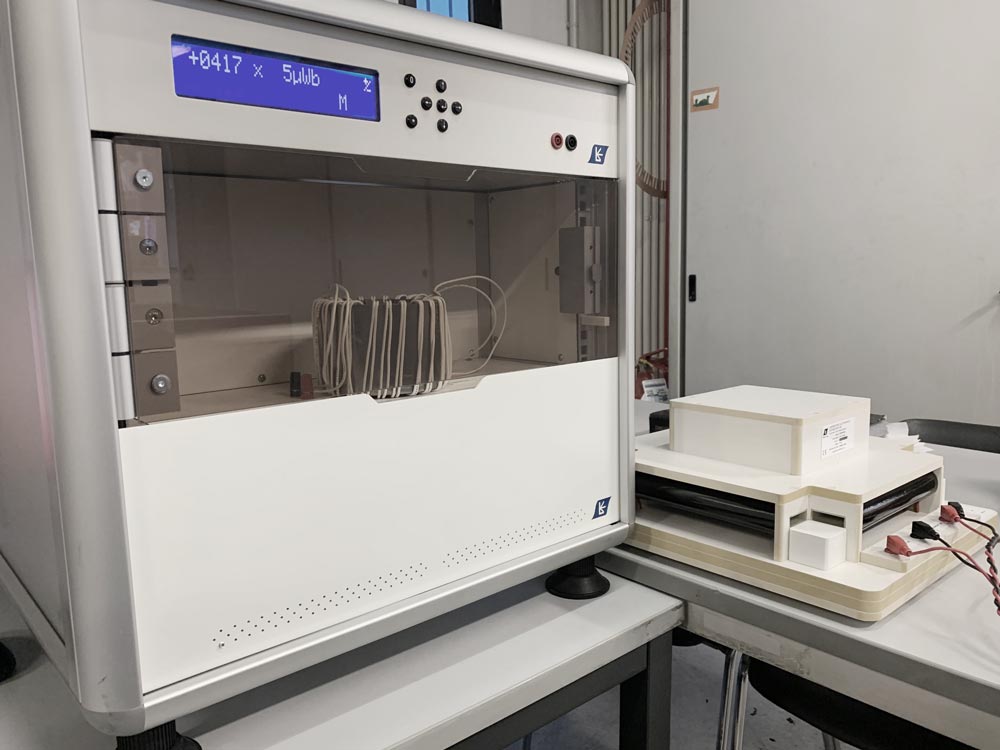

Magnetic Characterization of Materials:

VMF provides its customers with an AC/DC measurement system to test magnetic hysteresis cycle of stator and laminations.

Laser marking:

Labelling a production code on each stator and rotor gives traceability of the lot to which the part belongs.